ENEXAL Objectives

The primary aluminium production industry is the world’s larger industrial consumer of electrical energy and is ranked among the most CO2 intensive industries. It also generates enormous quantities of wastes that further decrease the exergy efficiency of its production process. However, this industry is one of the most vital sectors from economic and social point of view, not only for EU but also for the entire world. In order to remain viable and competitive, primary aluminium industry has to operate in a smarter way, be more energy efficient and meet the environmental requirements of our times.

This can be achieved only through radical new technologies and novel business strategies, which will enable the industry to maintain its competitiveness and fasten its viability in the world’s markets, and explore new business opportunities. The main goal of this project is to provide primary aluminium industry with “green” innovative technological and economical solutions, focusing on the:

A. Significant improvement of energy and exergy efficiencies of the production process

B. Substantial

reduction of GHG emissions

C. Complete

elimination of the solid wastes

In order to achieve this goal within the project, the ENEXAL project will demonstrate three novel technologies for the improvement of the primary aluminium production industry, which in sort are:

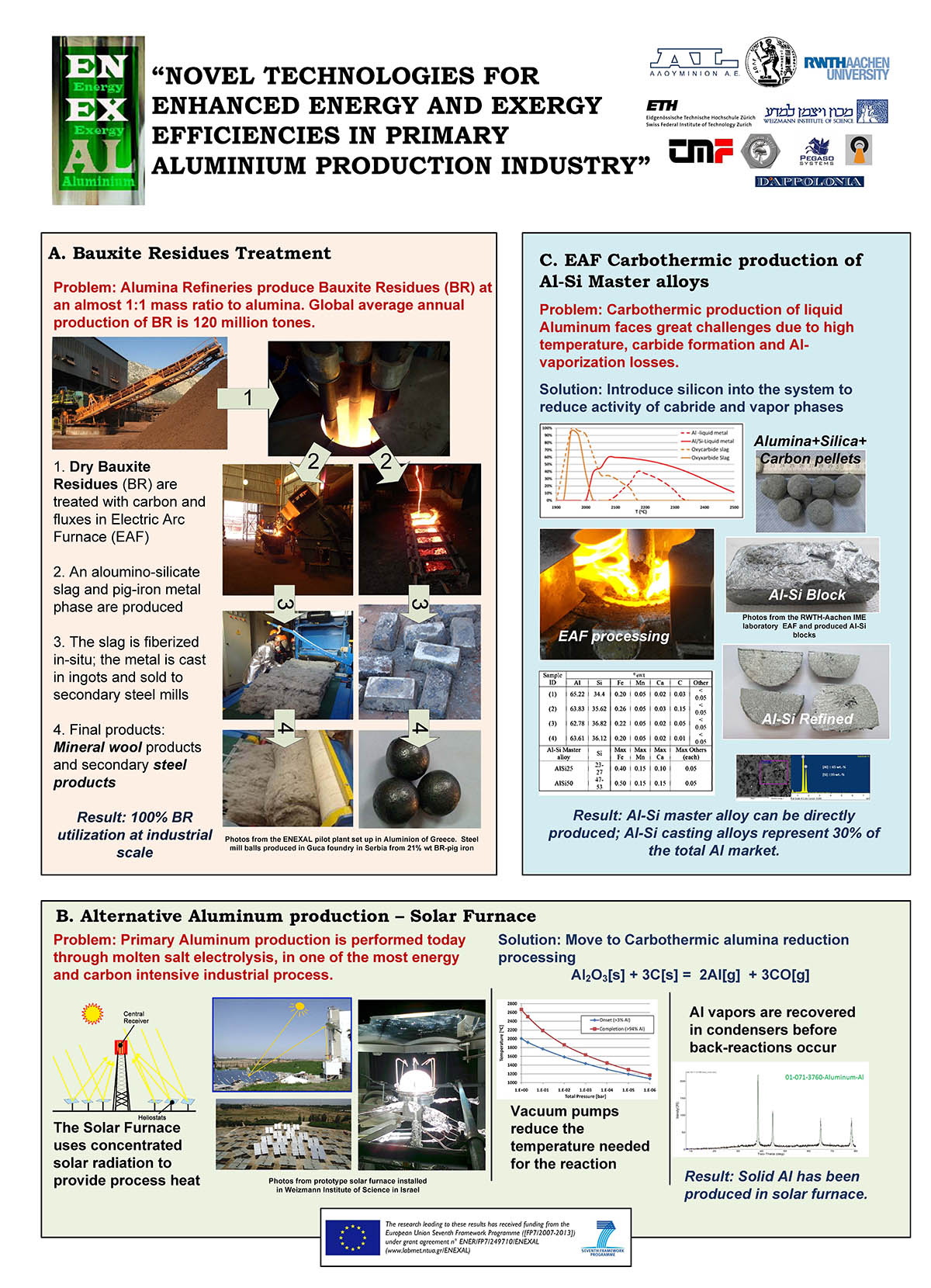

- The high temperature carbothermic reduction of alumina in an electric arc furnace (EAF), which will achieve up to 10% energy savings and up to 65% reduction in GHG emissions compared to Best Available Techniques currently used in industry.

- The moderate temperature carbothermic reduction of alumina in a novel solar furnace which can achieve up to 68% energy savings and up to 65% reduction in GHG emissions compared to Best Available Techniques currently used in industry.

- The red mud treatment in an innovative EAF, which will allow the total conversion of the red mud waste of the Bayer Process into valuable products, thereby increasing by 10 percentage points the exergy efficiency of the Bayer Process and eradicating its substantial environmental footprint (today approximately 2 kg of red mud are produced for every kg of primary aluminium) .

Technologies (I) and (III) represent technological solutions that relay on mature manufacturing technologies (e.g. EAF) and can be utilized directly in industrial production. Therefore both will be demonstrated under actual industrial conditions in the facilities of Aluminium of Greece (ALSA), which is the sole primary aluminium industrial partner involved in the ENEXAL project. ALSA will construct an industrial pilot plant, equipped with a 1 MVA- EAF (batch capacity 3500 kg), that will be used in both technology demonstrations. Each technology will be demonstrated in continuous operation over a 12 month period.

Technology (II) represents a ‘future’ technology utilizing concentrated solar radiation in an innovative solar furnace. As this kind of technology is still far from industrial applicability and its operation requires extensive optic facilities (a heliostat field and a solar tower), its demonstration will take place at the Weizmann Institute in Israel, which already posses unique optic facilities. The pilot testing of this technology will be conducted in smaller scale, batch experiments.

Following the demonstration and evaluation of these technologies a site optimization study will lead to the formation of a new primary aluminium production schema, integrating these novel technologies in current industrial practice and achieving further reduction of energy and CO2 emissions, while improving the energy and exergy efficiency of the whole process.

In the end, it is expected that the novel technologies demonstrated in the ENEXAL project, will play a key-role in the sustainability, competitiveness and viability of primary aluminium production industry, so as to render it a leader industry for energy-efficient technologies and products in Europe and worldwide.